BLANKING

Technologies

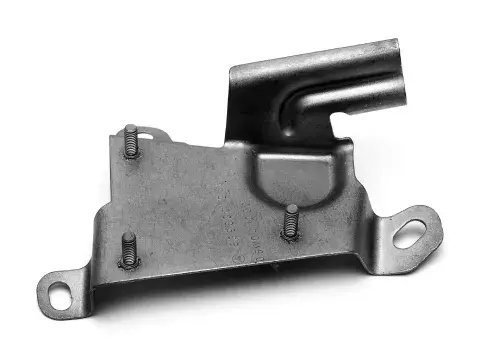

Blanking is a metal fabrication process by which a part is obtained from a primary metal strip or sheet when it is cut or perforated. The material obtained is used for further processing. Two of its advantages are that the tooling cost is much lower compared to the conventional press process, and that there is no waste of raw material.

Fields of application

This flat die-cutting process allows flat parts with perforations and reliefs to be obtained economically from coil, which will be the raw product from which car exhausts are made.

Typically, a die-cutting line for this type of product is designed to meet the high quality demands of automotive, white goods and other industries. This includes suppliers of flat parts or ‘face’ panels, which can be final parts or blanks for further processing into the shape of the final part.

Specialisation

At Atik Autmotive we manufacture blanks using automatic presses and coil feeders. We carry out cutting and marking of flat blanks and processing with trimming from coils.

Capacities

Automatic presses and coil feeders

Characteristics of the formats

- Coil width: up to 800 mm.

- Coil thickness: up to 3 mm.

- Force: 80 t.

Would you like more information?

Related applications