ELASTOFORMING

TECHNOLOGIES

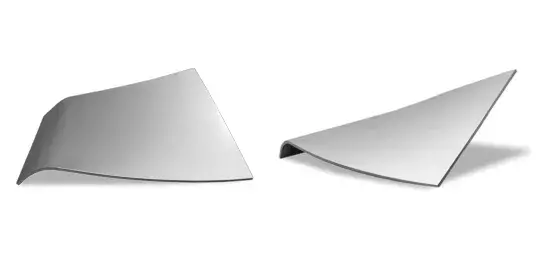

Elastoforming started out as a process of producing parts from flat sheets by forming them with rubber pads against a die for shallow parts. Subsequently, the same technique has been used for some tubular parts.

Process

Elastoforming allows tubes to expand by introducing an elastomer inside ,which is pushed by two hydraulic cylinders at each end against a die, allowing it to be formed on the outside. It is used to replace the hydroforming process in small series, due to the low cost of the dies.

The choice of elastomer is very important to achieve the desired effect. The material, mechanical and fatigue characteristics of the elastomer have to be taken into an account.

Low and medium volumes

The part acquires its final shape by forming it between two tools, one of which is rigid (often a metal punch or die) and the other is flexible (the rubber pad). Elastoforming is particularly suitable for low and medium volume production. Until recently, this forming was used almost exclusively in the aircraft industry.

Size and part variety

With elastoforming, a wide variety of sizes and high quality parts can be easily achieved, as well as multiple part configurations.

CAPACITIES

Vertical press with hydraulically actuated side pressure cylinders

Features

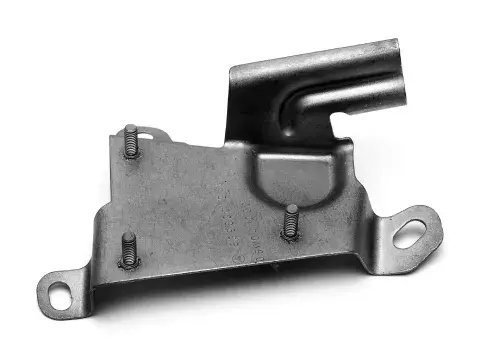

In Atik Automotive we have a vertical press with hydraulically actuated side pressure cylinders for this metal forming process. We have enhanced our knowledge around this technology and developed presses with hydraulic actuators that can obtain the desired forming. We also developed the necessary tooling for this purpose.

Would you like more information?

Related applications