PARTICLE CLEANING

Technologies

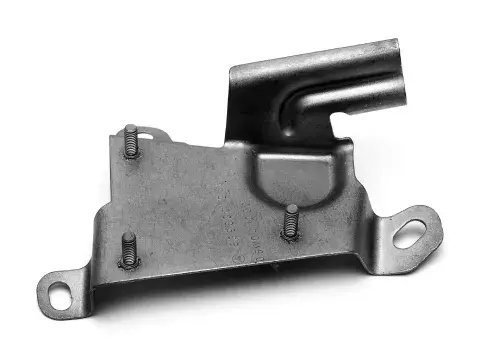

The need for component cleaning in highly demanding sectors, such as the automotive and aeronautical sectors, has increased in recent years to the point where it has become an essential element in the supply of certain parts.

Thus, the cleaning of industrial parts does not only involve degreasing or removing visible residues from the manufactured parts. It is a technical cleaning that is capable of removing all types of mechanical, liquid and chemical contaminants.

Areas of application

In the manufacture of components, different contaminants accumulate in them, which can be organic (oil, grease, wax, …), inorganic (emulsions, salt, fingerprints, dust, …) and mixed organo-mineral (polishing and burnishing pastes, …).

Therefore, the cleanliness requirements can be very different, depending on the production processes used and the elements incorporated in the production, such as drilling oils, oils, etc., as well as the final use of these components.

We identify three types of cleanliness requirements:

– Degreasing of components

– Removal of particles

– Removal of mineral stains

In the control of the results, test methods and standards appropriate to the required level of cleanliness must be used. These include the visual cleanliness or white cloth test, the Dyne ink test (surface tension), particle size analysis, gravimetric analysis, the non-volatile residue test and the residual moisture test.

Cleaning technologies

The most appropriate cleaning technology depends on four interrelated parameters, which are:

– Chemistry. Based on the basic rule “like dissolves like”, we know that solvent media dissolves organic contamination and aqueous media dissolves inorganic contamination.

– Time. This parameter includes the total processing time required for cleaning, rinsing and drying to meet the desired cleaning result. If the total time exceeds the required processing cycle time, it will have a serious impact on the choice of cleaning equipment.

– Temperature. Temperature influences both the quality of the cleaning , the drying effect and the overall process time.

– Mechanical action. The introduction of mechanical treatments greatly influences the cleaning results and also the processing time required. There are different technologies, each with advantages and weaknesses depending on the application.

Would you like more information?

Related applications