BRAZING

Technologies

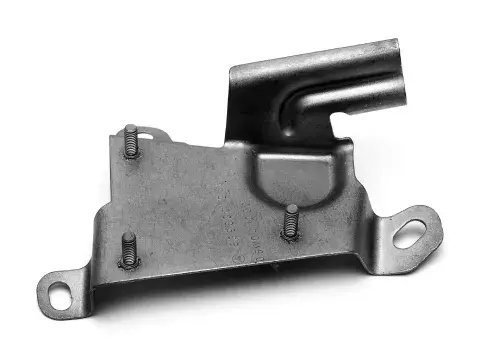

Brazing is a type of welding that consists of the thermal joining of metal parts. This is done by maintaining a welding temperature below the melting point, above 450ºC.

Fields of application

Brazing is widely used in the automotive industry and is also commonly used in the electronics, electrical, aerospace and construction industries.

Specialisation

In Atik automotive we apply the best type of brazing welding for each project using different methodologies such as torch, resistance welding, oven, infrared, laser or induction.

The industrial use of brazing provides multiple benefits in addition to those intrinsic to the heating itself. These are selective heating, better joint quality, reduced oxidation and acid cleaning, fast heating cycles and more consistent results.

Advantages of Brazing

- Smooth, clean edges and a glossy finish are achieved.

- No finishing is required

- Different materials can be welded together

- The parts to be joined do not lose their properties and are not affected in their structure.

- It gives the possibility to make complex cross-section joints

- A high strength joint is achieved (up to 50 kg/mm2)

- High efficiency

- Low cost

Would you like more information?

Related applications