Climate change has been a major concern around the world for some years now, and we at Atik are aware of this.

In terms of road transport, regulations are becoming increasingly restrictive due to greenhouse gas emissions. Car manufacturers must therefore come up with vehicle designs that comply with these new regulations.

One of the means to reduce pollutant emissions is the use of after-treatment devices. Most modern vehicles are designed to incorporate an exhaust gas recirculation (EGR) system.

But what is an EGR system? As we will see, in view of the increasing pressures to reduce emissions, the EGR valve is an essential element of the vehicle, which will play an increasingly important role in the future.

Exhaust gas recirculation

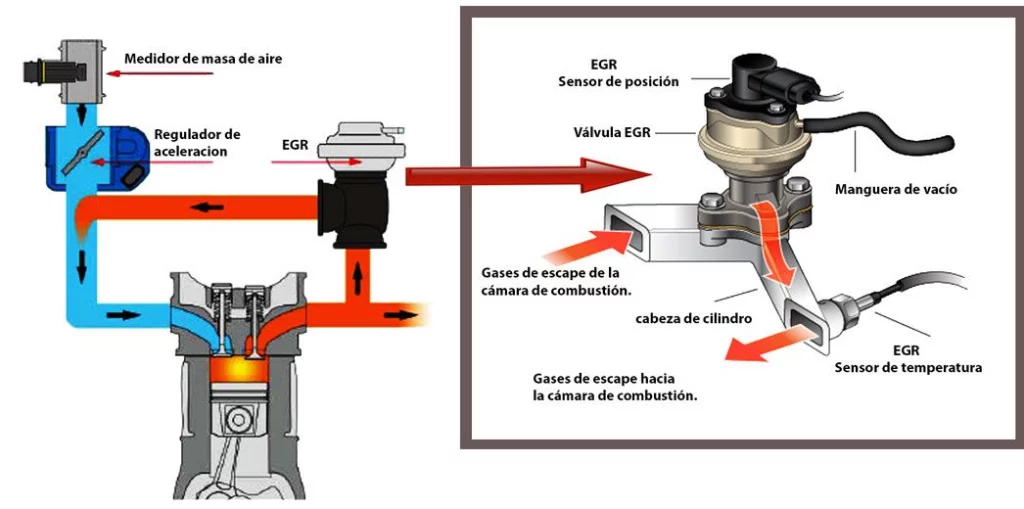

EGR (Exhaust Gas Recirculation) valves are used in internal combustion engines to reduce the amount of nitrogen oxides (NOx) released from the exhaust. Internal combustion engines burn fuel in a combustion chamber to produce energy that drives the vehicle. During combustion, air and fuel combine to generate power. However, this also produces nitrogen oxides, which are a form of pollution.

What this mechanism does is recirculate a small amount of exhaust gases (containing nitrogen oxides) back into the combustion chamber. This reduces the amount of oxygen in the chamber, which reduces the combustion temperature. As a result, less NOx emissions are produced.

In other words, it is a key component of an engine’s emission control system. Its function is to reduce the amount of nitrogen oxide (NOx) and hydrocarbon (HC) emissions produced by a diesel engine.

Nitrogen oxides (NOx)

Nitrogen oxides (NOx) are a common by-product of fossil fuel combustion in internal combustion engines. During combustion, airborne nitrogen and oxygen gases react and form NOx, especially at high temperatures. These are a major component of smog and can be harmful to human health and the environment.

Incorporating exhaust gas recirculation (EGR) systems into vehicle design is an effective way to reduce harmful emissions. It is therefore also important to protect the environment and human health.

How does an EGR valve work?

As mentioned above, the EGR valve regulates the amount of exhaust gas recirculation in the engine. In terms of how it works, we also know that its position varies from fully closed to fully open, although it can vary anywhere in between.

When the engine starts, the EGR valve is fully closed. As the engine idles or at low speeds, the EGR valve gradually opens to allow recirculated exhaust gases to enter. During hard acceleration, the EGR valve closes to allow the maximum amount of oxygen into the cylinder to increase engine power.

The EGR valve can also improve combustion efficiency in GDi engines by reducing pumping losses and improving knock tolerance. In diesel engines, it can help reduce engine noise and diesel knocking at idle.

In addition to reducing nitrogen oxides (NOx), EGR valves also regulate the mixture of air and fuel entering the intake manifold, which improves fuel economy and reduces emissions of other pollutants. EGR valves are responsible for reducing NOx emissions by 50% to 90%, depending on the design of the engine and the EGR system.

It is therefore a key component of a vehicle’s emission control system.

The importance of EGR valves in a car

In addition to the above, EGR valves have other benefits. One of them is that they can help extend engine life. High combustion temperatures can damage engine components, especially in engines with high compression ratios. The EGR valve helps to reduce combustion temperatures, which can reduce wear on internal engine components and extend engine life.

In addition, EGR valves can also improve the engine’s throttle response in certain situations. When accelerating hard, the EGR valve may close to allow more fresh air and fuel into the engine, which increases power and throttle response. On some vehicles it may also open in high load situations to increase engine power.

Types of EGR valves

Although there are many types of EGR valves, the main ones can be grouped as follows:

High-pressure diesel EGR valves divert high-flow, carbon-laden exhaust gases before they enter the diesel particulate filter: the carbon can combine with oil vapour to create sludge. The gases return to the intake manifold through a pipe or internal holes in the cylinder head. A secondary valve is also used to help create a vacuum in the intake manifold, as this is not naturally present in diesel engines.

Low-pressure EGR valves for diesel engines divert the exhaust gas after it has passed through the diesel particulate filter: this gas has a slower flow but is almost completely free of carbon. The gas is returned to the intake manifold through a pipe.

Gasoline EGR valves divert exhaust gases, much like the high-pressure diesel equivalent. The vacuum created by the negative pressure in the cylinder draws in the exhaust gases and the flow is regulated by the opening and closing of the EGR valve itself.

Vacuum operated EGR valves use a vacuum solenoid to vary the vacuum to the diaphragm to open and close the EGR. Some valves also include a feedback sensor to notify the ECU of the valve position.

Digital EGR valves have a solenoid or stepper motor and usually a feedback sensor. These valves receive a pulse width modulated signal from the ECU to regulate the exhaust gas flow.

Conclusion

At Atik Automotive we are experts in EGR valves. We know that these parts are essential for your vehicle and that is why you need to make the best choice. As manufacturers and suppliers of EGR valves we offer you the best technology and absolute guarantee of quality.

Find out more about our emission management parts.